INSTALLATION RECOMMENDATIONS FOR KNUMOX ELEMENTS ON WALL PANELS, L-STONES OR PRECAST CONCRETE ELEMENTS

The KNUMOX aluminum block can be attached to a wall panel if this is permitted or approved by the manufacturer's structural analysis / static calculation. It is necessary for the planner and/or the responsible specialist company to clarify this independently with the manufacturer of the precast concrete elements in advance. When mounting on the corresponding precast concrete elements, the aluminum block is not fastened using the V4A drive-in anchors supplied, but is fastened using sufficiently dimensioned adhesive anchors. The adhesive anchors can be obtained from KNUMOX on request. The work steps are otherwise the same as for installation on a concrete foundation provided by the customer. The drilling depth and the dimensioning of the drill holes must be adapted independently to the corresponding system. Due to the applied load and the KNUMOX system, it may be necessary to adjust the dimensions of the foundation for the prefabricated part. In this case, you must contact the manufacturer independently for approval.

-

- Attention: drilling may cause chipping of the concrete parts.

- Attention: the wall panels or prefabricated parts are usually reinforced with steel, in this case it must be clarified beforehand with the manufacturer whether he gives approval for the installation of the KNUMOX elements.

- KNUMOX assumes no liability for statics, damage or any consequential damage that may arise due to installation.

- The additional pressure exerted by wind load or persons on the component (L-stone, angle support, precast concrete element) must be taken into account,

- It is strongly advised not to have the installation carried out by a non-qualified person.

- The applicable standards and safety guidelines must be observed during installation.

-

Installation of the KNUMOX aluminum block

Align the aluminum block on the precast concrete part and place it in the desired alignment. The holes in the aluminum block are predefined; mark the holes on the precast concrete part. The aluminum block, with the predefined holes, serves as a template.

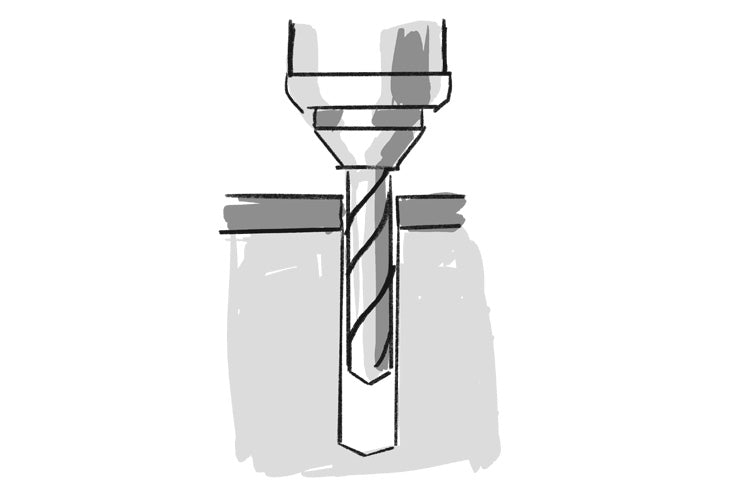

1. Drill holes with a drill (masonry drill for concrete) with a diameter of 10 mm, approx. 105 mm deep.

2. Blow out/vacuum and clean the holes using an industrial vacuum cleaner or a blower. Then replace the aluminum block.

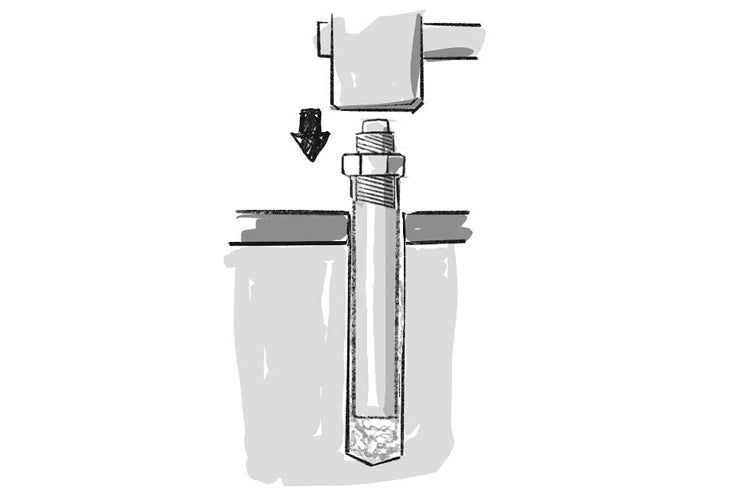

3. Fasten the aluminum block using sufficiently dimensioned adhesive anchors: Insert the composite mortar cartridge.

Do the text and image match?

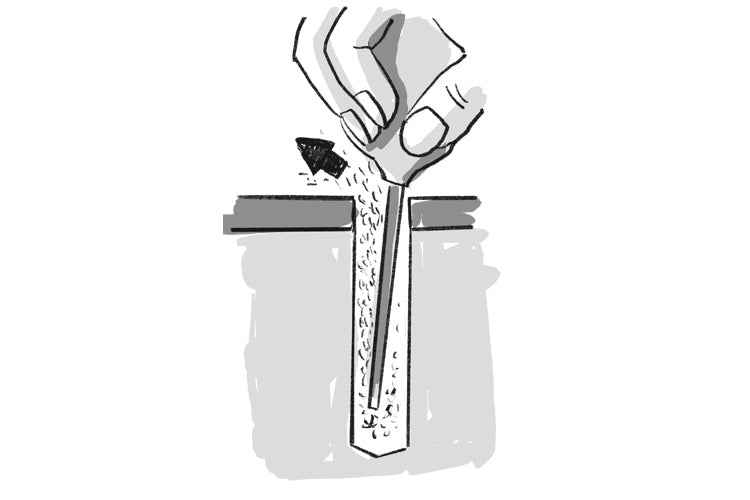

4. Drive in the anchor rod.

Do the text and image match?

must then be added as the next step:

Tighten the hexagon nuts with a torque wrench to 25 Nm.

Note: the aluminum block must lie flat.

or before that something like "After the glue has hardened"

Inserting the KNUMOX glass element

Before inserting the glass element, the following steps must be carried out:

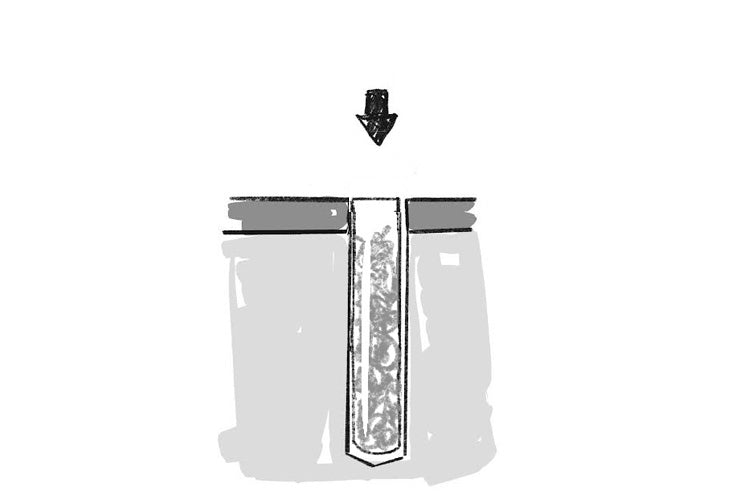

5. Insert the rubber seal (flat, finely grooved) flush into the prefabricated groove of the aluminum block.

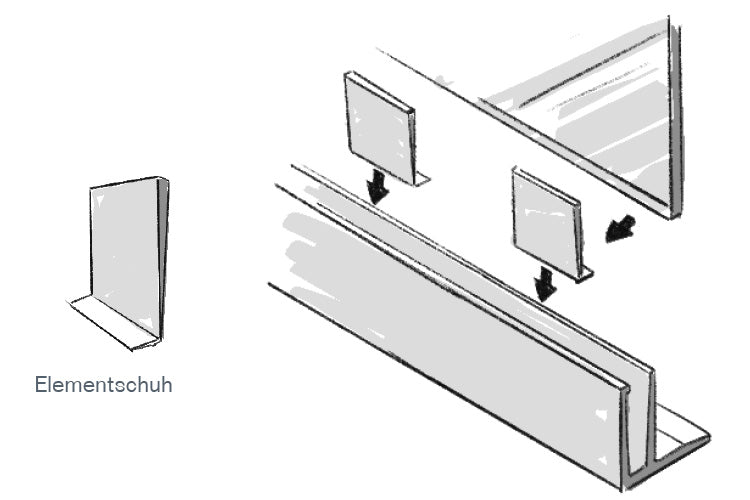

6. Insert the element shoes into the aluminum block. Distribute these evenly over the appropriate length. Then carefully insert the glass element into the aluminum block (on the white “shoes”) and hold it.

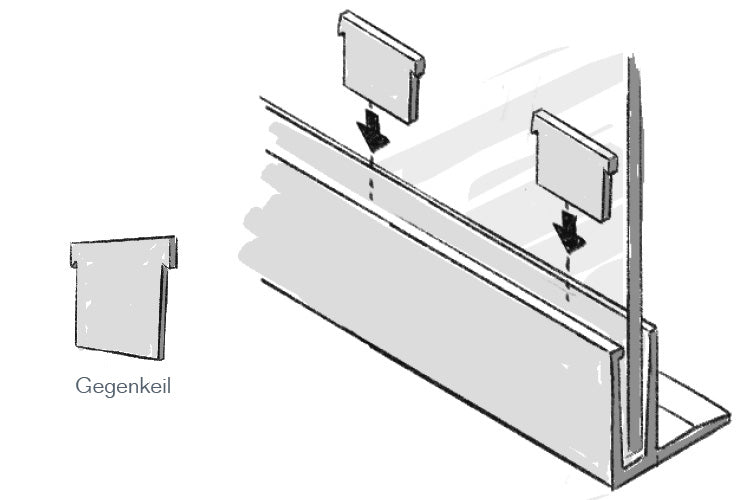

7. Opposites on opposite side with the smooth side

to the glass. Then press these firmly in with a tool (flat screwdriver) the Knumox impact tool so that the glass element is firmly seated, at least deep enough for the rubber to fit over it later.

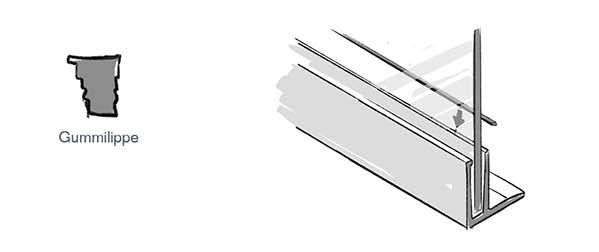

8. Insert the remaining rubber lip and press it in firmly.